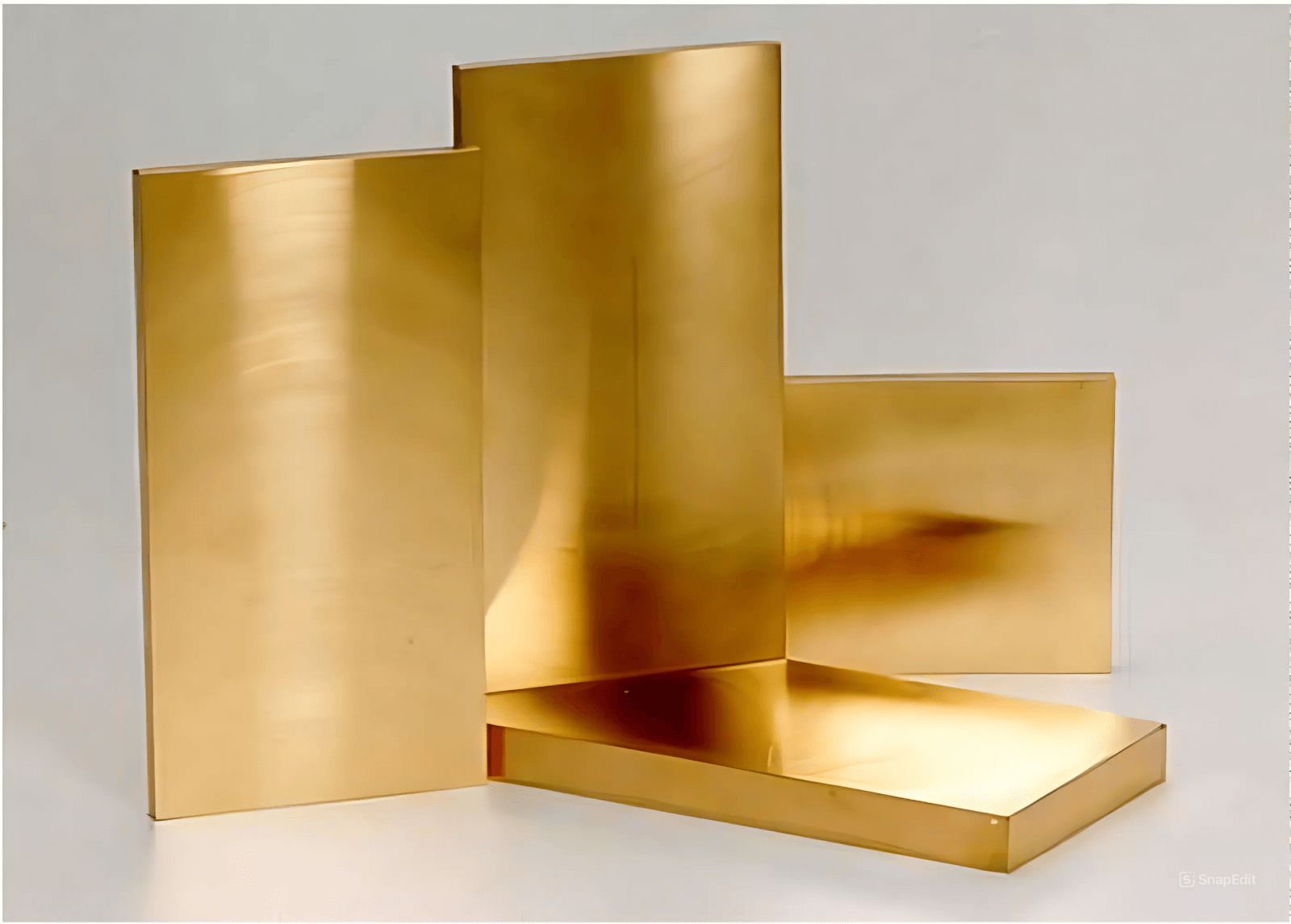

Copper Tungsten Plate

Electrotool

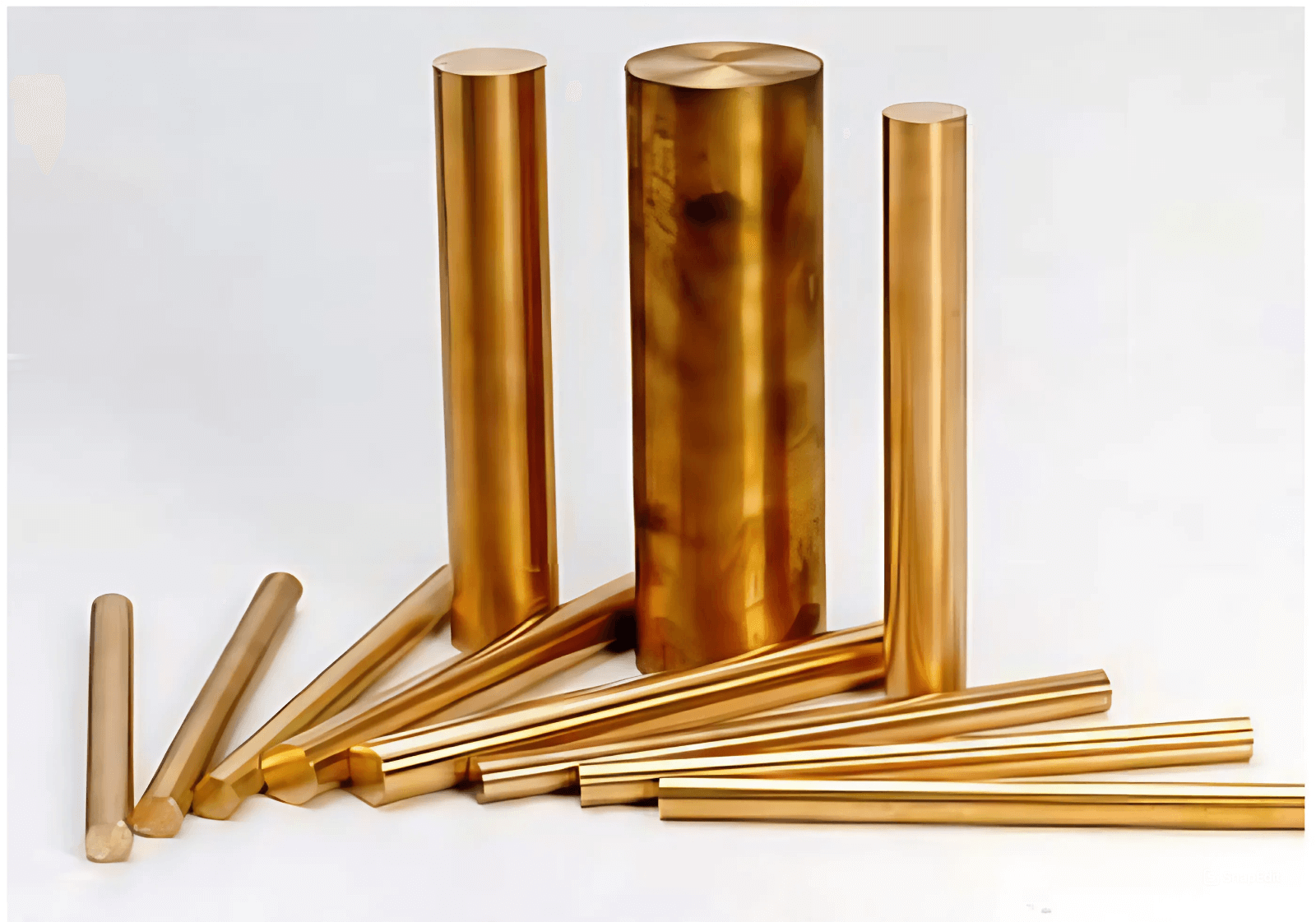

Shercut copper-tungsten and silver-tungsten are manufactured as materials for EDM (Electric Discharge Machining). Shercut materials are also manufactured by the power metallurgy techniques of pressing, sintering, and infiltrating tungsten with copper or silver. Shercut is produced under the same rigid manufacturing, fixed and strict quality control supervision. This assures a high performance electrode providing greater cutting stability, excellent machnability and reduced down time. For extremely close tolerance work, Shercut maintains dimensional accuracy and will have longer operating life due to the high metallurgical integrity found in our copper or silver-tungsten electrode materials.

| t | 100 X 100 | 75 X 200 |

|---|---|---|

| 1 t | • | |

| 1.5 t | • | |

| 2 t | • | |

| 3 t | • | |

| 4 t | • | |

| 5 t | • | |

| 6 t | • | |

| 7 t | • | |

| 8 t | • | |

| 9 t | • | |

| 10 t | • | |

| 11 t | • | |

| 12 t | • | |

| 13 t | • | |

| 14 t | • | |

| 15 t | • | |

| 16 t | • | |

| 17 t | • | |

| 18 t | • | |

| 19 t | • | |

| 20 t | • |

| 100 X 100 | 75 X 200 | |

|---|---|---|

| 25 t | • | |

| 30 t | • | |

| 35 t | • | |

| 40 t | • | |

| 45 t | • | |

| 50 t | • |

Specifications

| GRADE | ( Cu-W ) | ( Cu-W ) |

|---|---|---|

| Compostion | 25Cu + 75W | 30Cu + 70W |

| Gravity | 14,85 | 14,3 |

| Conductivity | 4 | 4 |

| '% ACS | 5 | 5 |

| Density | HRB 98 | HRB 93 |

| Resistance | 3 | 3 |

| Arc | 0 | 0 |

| Weld | 0 | 0 |

| Waste | 1 | 1 |

| Tension | 1 | 1 |

Copper Tungsten Rod

| ø | 100 mm | 200 mm |

|---|---|---|

| 1 ø | • | |

| 1.5 ø | • | |

| 2 ø | • | |

| 3 ø | • | |

| 4 ø | • | |

| 5 ø | • | |

| 6 ø | • | |

| 7 ø | • | |

| 8 ø | • | |

| 9 ø | • | |

| 10 ø | • | |

| 11 ø | • | |

| 12 ø | • | |

| 13 ø | • | |

| 14 ø | • | |

| 15 ø | • | |

| 16 ø | • | |

| 17 ø | • | |

| 18 ø | • | |

| 19 ø | • | |

| 20 ø | • |

| ø | 100 mm | 200 mm |

|---|---|---|

| 21 ø | • | |

| 22 ø | • | |

| 23 ø | • | |

| 24 ø | • | |

| 25 ø | • | |

| 26 ø | • | |

| 27 ø | • | |

| 28 ø | • | |

| 29 ø | • | |

| 30 ø | • | |

| 35 ø | • | |

| 40 ø | • | |

| 45 ø | • | |

| 50 ø | • | |

| 60 ø | • | |

| 70 ø | • | |

| 80 ø | • | |

| 90 ø | • | |

| 100 ø | ||

| 120 ø | ||

| 150 ø |